以下是我们的加工设施以及各种类型的原型设计和生产服务。

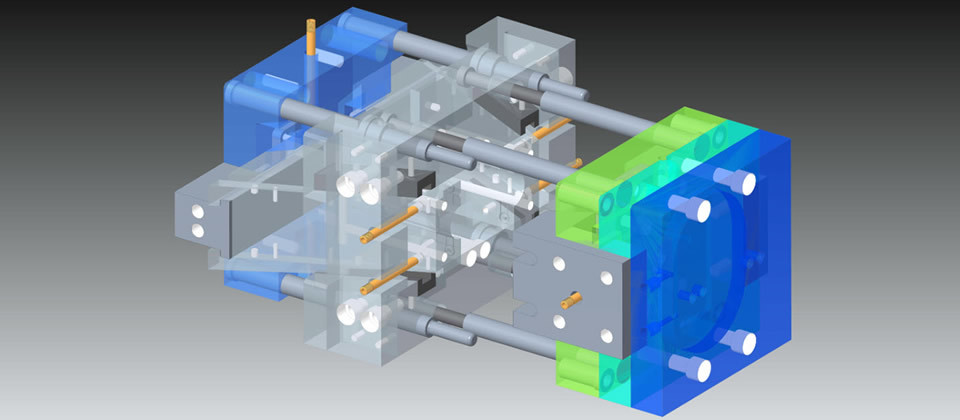

注塑成型可以帮助您使用不同种类的塑料材料生产出成千上万的塑料零件. 这种制造方法适用于生产较大批量的订单。

我们专业生产质量非常好的塑料注塑件和模具工具。我们可以提供机械加工和精加工服务,使用各种材料制作工具,并可以生产50-100,100+各种塑料的成品零件。凭借强大的供应链,我们可以满足您各种规模的项目需求

我们有各种材料,可以满足您对我对模具和注塑件的所有需求。请参阅列表。

另外说明,否则我们遵守DIN 162742塑料注塑成型的标准公差。

我们的CNC加工服务包括车床, 电火花和线割,外圆磨等。这将帮助您有效的制造快速工具和零件

通过使用先进的设备,我们可以提供各种CNC加工服务,包括铣削,车削,EDM,线切割,表面磨削等等。我们的工人使用我们进口的3、4、5轴CNC加工中心,用不同的种类的塑料和金属材料制造车削和铣削零件。凭借强大的供应链,我们可以满足您各种规模的项目需求

我们使用市场上几乎所有类型的材料来制造您的CNC零件和原型件。如果您需要,我们可以使用您提供的特定材料。请参阅我们的CNC加工材料清单。

我们对金属CNC加工的一般公差是DIN-2768-1-精细,对于塑料的一般公差是DIN-2768-1-中等。如果您需要,我们将与您确认任何特定项目。

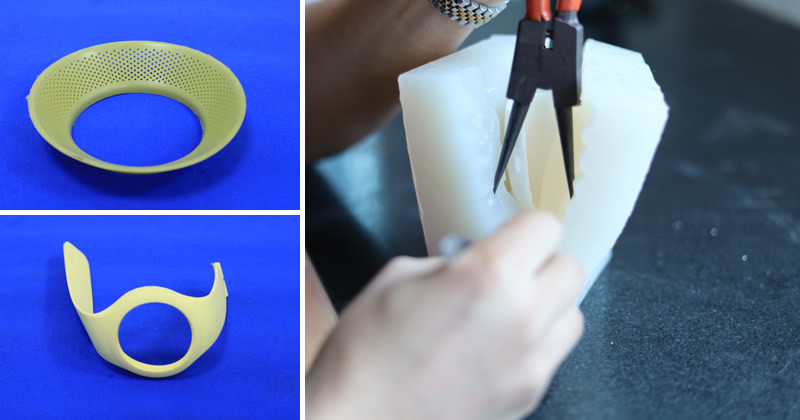

它非常适合制作高质量的原型或由硅胶复模形成的小批量产品。 这些复制品 反映了出色的表面细节,并且可以与原始图案相匹配。

这种加工方式是一种生产高质量原型或小批量零件的方法,这些零件是由廉价的硅胶模具制成的。这些复制品反映了出色的表面细节,并且可以与原始图案相匹配。

我们可以使用多种铸造聚合物来复制不同种类的硬度和表面纹理。如果需要,我们还可以达到完全透明完全不透明、半透明、完全透明的效果。查看关于可用材料的更多信息。

真空铸造件的公差是不同的。这取决于原始图案、零件尺寸和我们使用的材料。通常收缩率为0.15%

有时我们会使用3D打印来生产复杂形状的零件,这些零件无法通过 传统的机械加工或其他方法生产。

SLA是指立体光刻,这是一种基于立体树脂的3D打印技术。印刷是在紫外线的帮助下进行的,紫外线会影响液态树脂并根据需要将其固化成固体层。

SLS是指选择性激光烧结,这是一种3D打印技术,它使用粉末打印材料而不是树脂来创建3D对象。与SLA类似,该过程也使用激光来促进3D打印过程。

伯丰投资于优秀的人才和最现金的设备,以实现正确的组合,生产出精密的产品。了解我们的设备...

我们可以提供原型设计和生产解决方案,以缩短产品开发时间。

表面处理是指使有原型零件的表面具有特定外观的不同过程。以使其具有独特或所需的外观和感觉。使用不同的技术来达到效果。

伯丰为通过各种制造方法生产的所有组件和零件提供高质量的表面处理服务。我们有一支技术娴熟的团队,可以正确和专业地完成工作。 查看有关完成细节的更多信息。