Quality Inspection

我们公司严格的质量保证流程

我们严格执行 ISO 质量程序和标准,并已获得 ISO 90001:2024 认证。这意味着我们的生产线拥有先进的技术,可提供精确的制造精度和准确度结果。我们使用所有内部先进的测量和测试设备来检查所有来料和精加工零件,以满足您的规格要求。这就是为什么我们是中国最好的快速原型公司之一。详细了解我们的质量控制系统。

内部来料检验设备

我们公司拥有内部先进的检验、测量和测试设备,检查所有进货原材料。我们对所有材料进行测试,并为进入我们生产线的每件材料提供材料可靠性鉴定 (PMI)。您应该完全有信心,您收到的零件将达到或高于您的预期。

FTIR 红外光谱仪

这是我们在生产前检查所有进货原材料的机器。这是为了确保材料的准确性。只是提醒您,并非所有制造商都会为您执行此操作。

PolyMax 喷枪

我们每天在生产中使用各种各样的塑料材料。为了确保质量和材料的准确性,我们使用 polymax 喷枪进行材料识别测试。

直读光谱仪(OES)

直读光谱法 (OES) 是一种广受信赖且广泛使用的分析技术,用于测定多种金属的元素组成。

使用 OES 可以测试的样品类型包括初级和次级金属生产以及金属加工行业中的熔体样品,包括管材、螺栓、棒材、线材、板材等。

我们使用了很多种金属 ,其中许多看起来很相似,在市场上不容易识别它们,其中一些是贴错标签或假冒材料。我们可以为所有进货材料提供材料可靠性鉴定 (PMI),因此您可以相信我们,您收到的正是您订购的。

XRF 分析仪

X 射线荧光(XRF)分析仪可对镁(Mg)到铀(U)进行快速、无损的元素分析,分析范围从百万分之几到 100%。在现场使用以获得即时结果,分析器提供的数据可以帮助确定下一步行动方案,何时何地需要。

零件质量检查设备t

通过使用各种最终检验设备,我们能够进行生产质量控制,并确保我们制造的零件能够满足您的设计规格。质量检验部门是我们生产线的重要组成部分。

SmartScope ZIP Lite 300 系列

SmartScope ZIP Lite 300 配备了 MeasureMind 3D MultiSensor 计量软件,提供完整的 3D 测量功能和先进的测量算法。

它是一种非接触式光学测量系统。它可以快速编程以运行多个相似形状的自动测量。

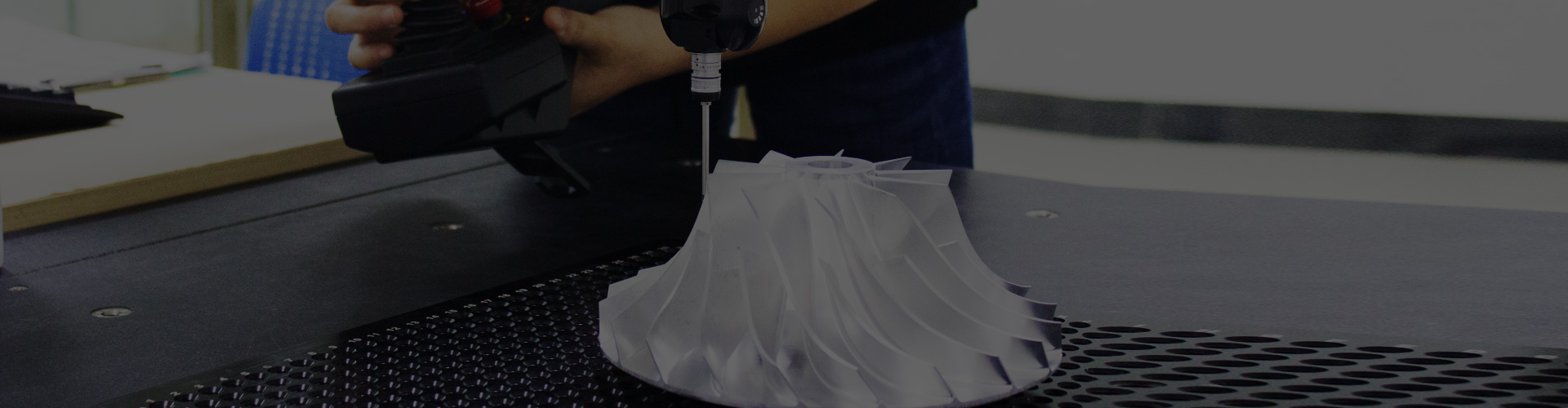

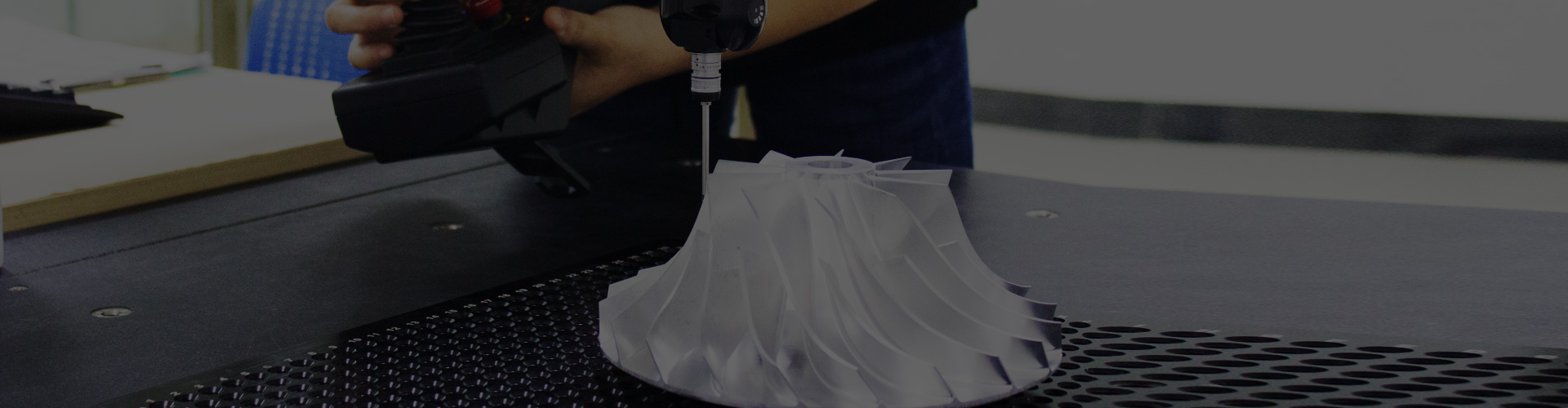

三次元测量机

坐标测量机 (CMM) 是一种通过使用探头感应物体表面的离散点来测量物理物体几何形状的设备。CMM 中使用各种类型的探头,包括机械、光学、激光和白光。根据机器的不同,探头位置可能由操作员手动控制,也可能由计算机控制。坐标测量机通常根据测头从三维笛卡尔坐标系(即 XYZ 轴)中参考位置的位移来指定测头的位置。除了沿 X、Y 和 Z 轴移动探头外,许多机器还允许控制探头角度,以便测量原本无法到达的表面。

Tesa-Hite(高度仪)

先进的新品 Tesa-Hite 仪器可以非常准确的数据测量产品的高度。这确保我们将为您提供完美的零件。