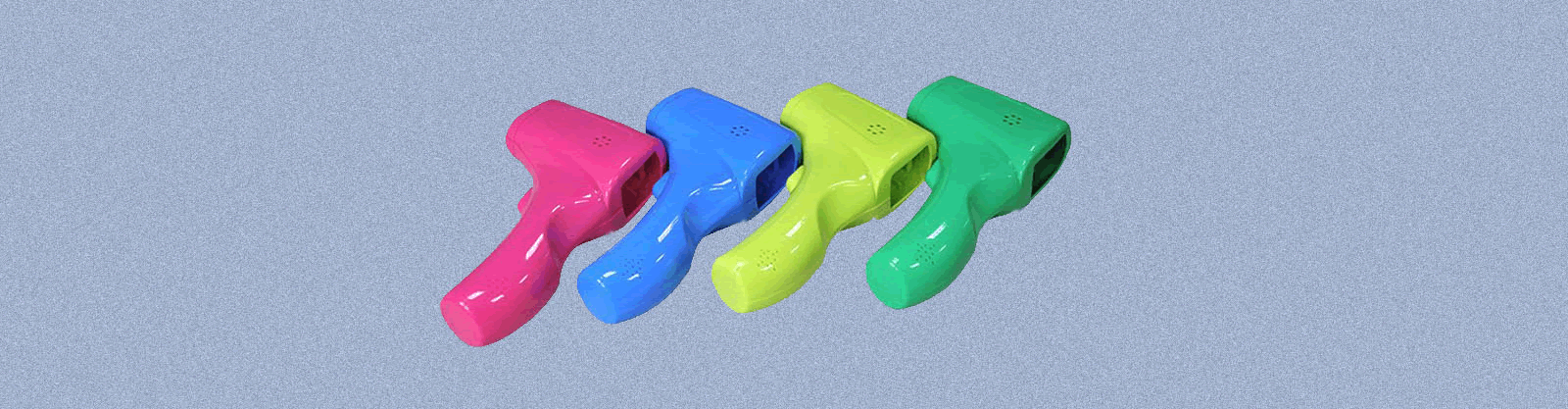

我们公司可以制造高质量的注塑件和模具工具。

我们可以提供机械加工和精加工服务,用多种材料制造工具,并且可以生产 50 到 100,000+ 多种塑料成品零件。

我们可以通过我们的 QA 系统和先进的机器确保您的工具和零件超出您的需求预期。如果您要开始下一个项目,请立即上传您的产品设计信息。

塑料注射成型是生产许多工业产品大批量成品塑料零件的最流行方法。在高压下,将熔融树脂注入金属模具的腔体中,然后迅速冷却,然后形成固体形状。它可以在几秒钟到几分钟内制造零件,具体取决于零件的大小和复杂性。

成型过程包括以下基本步骤:

我们提供硬质模具(型芯和型腔)服务以及各种材料,以更好地满足您对成本、数量和生产时间的需求。您还可以订购特殊金属。了解关于我们的快速成型模具模具服务的更多信息。

几乎所有的塑料材料都会在热和湿气的作用下碰撞和收缩。我们的公差等级将对此给出大致的概念

我们将尽最大努力改进您的制造设计。我们将指出不良设计可能导致热应力、收缩、翘曲等的任何区域。请参阅我们的设计指南,了解有关常见缺陷以及如何避免它们的更多信息。

除非另有规定,否则我们遵守DIN16742塑料注塑成型标准公差。

注塑成型使用什么塑料?

通常,我们可以在注塑成型过程中使用任何类型的塑料。我们有数以千计的热成型和热固性塑料可供您的项目使用。查看我们的常用材料清单。

塑料注射成型有哪些优势?

塑料注射成型是生产数十万个成品零件的最快、最具成本效益的方法之一。

制作注塑模具需要多长时间?

您可能需要一到两周的时间来制作模具工具。这取决于设计和热处理工艺的复杂程度。