我们还提供全系列压铸服务。如模具工具制造、压铸、机械加工、抛光和电镀。通过我们严格的质量检验,我们可以确保您的原材料和成品零件的质量。欢迎将试用部件发送给我们测试。

压铸成型是一种工艺,其中熔融金属在压力下被迫进入安全锁定的金属模腔,在那里由强大的压力机固定,直到金属凝固。通常,当熔融金属仍保持在模具中时,会施加压力。

模具的质量可以决定您的压铸项目是否成功。

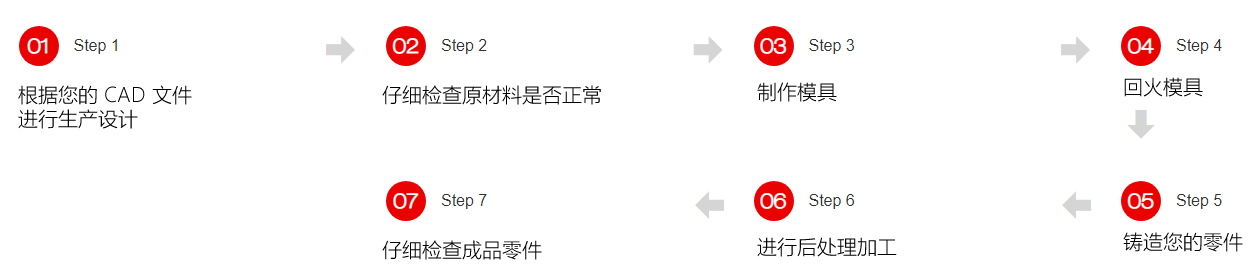

我们是中国最好的工具制造制造商之一。当我们收到您的订单后,我们将:

通常我们基于标准的通用 NADCA 公差。但是,如果您有具体要求 ,那么我们将与您确认是否可以遵循您的要求。

模具

我们通常使用洛氏硬度为 13-42 的 H48 工具钢。如果您需要,我们也可以使用特种钢材。阅读更多关于我们的快速模具服务的信息。

压铸件

我们可以使用不同的金属进行铸造。您需要的材料取决于成本、重量和性能。以下是一些提示:

- 铝材适用于坚固、轻便和复杂的形状。它也可以高度抛光。

- 锌更便宜,适合电镀。

- 镁是更高性能应用强度重量比的最佳选择。